Imagine a world where your favorite dishes like juicy cheeseburgers and sizzling steaks come not from farms but from printers. This is the reality of 3D-printed meats. Scientists and chefs are coming together to use advanced technology to create meat in labs. These protein-packed meals are feeding the world in a new, sustainable way.

It’s promising to reduce harm to the plan while still offering the tastes and textures you love. Yet, is there a catch to eating 3D-printed meat? While the technology and science behind it sound promising, some may find it questionable. Either way, you can decide when exploring the concept of printed meals.

What Is 3D Printed Meat Made of?

Three-dimensionally printed meat is a cultured or lab-grown meat that looks, cooks and tastes like real food. However, it’s produced in an entirely different manner. Instead of harvesting the meat from animals, it’s created through the animal cells.

Scientists start with a small sample from various sources such as muscle, fat or connective tissue. These cells are then nurtured in a nutrient-rich environment, allowing them to grow and multiply.

The primary ingredients are the cells and a scaffold that gives meat structure. Additionally, there’s a nutrient solution known as a growth medium to feed the cells as they develop. The growth medium is a mixture of amino acids, sugars, vitamins and minerals that support cell growth.

As these cells multiply, they form tissue similar to animal muscle tissue. This process enables meat production without having to raise or slaughter animals.

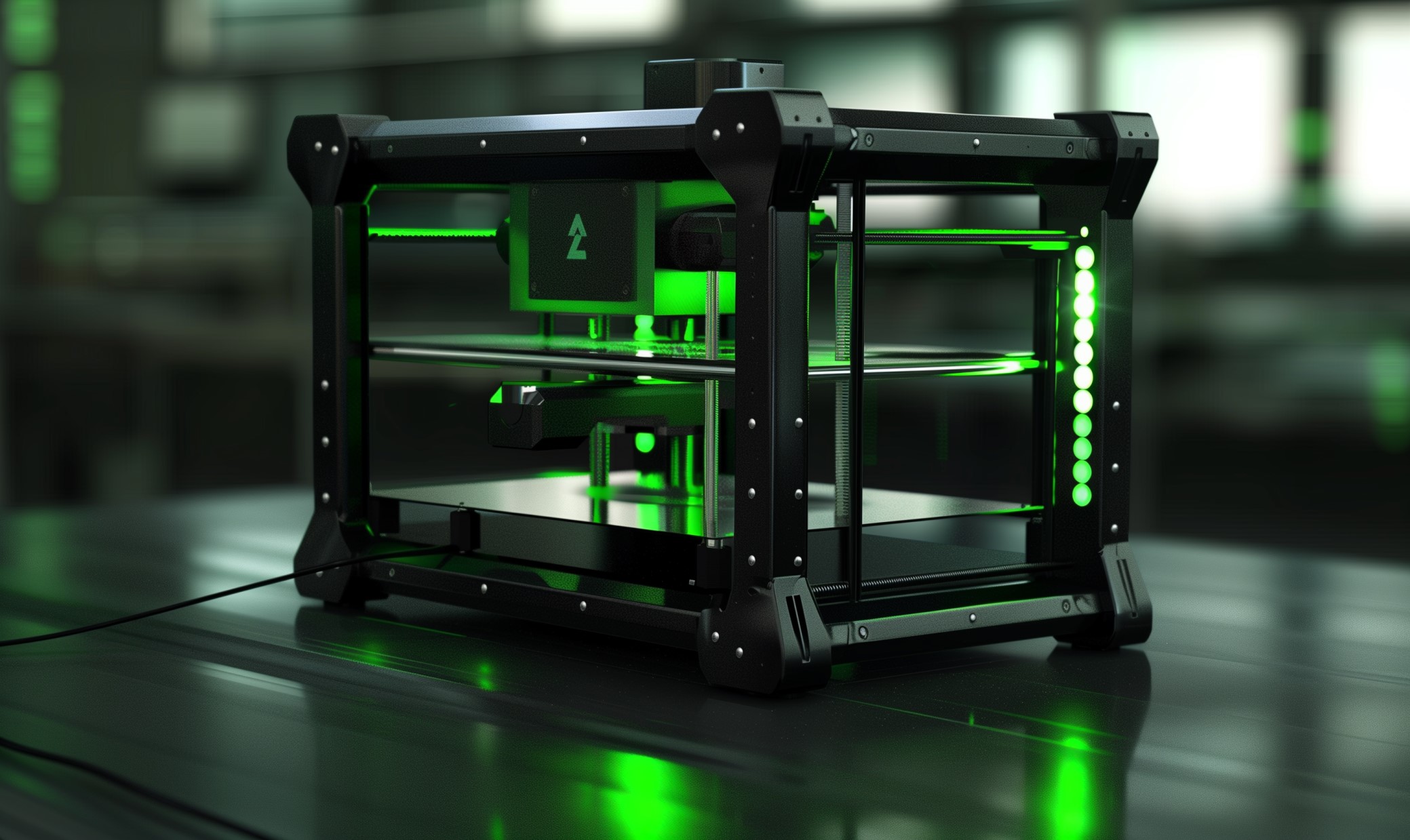

How the Meat Is Created Through 3D Printing

Printed meats are a fascinating creation process that merges the fields of biotechnology, culinary arts and environmental science. The steps begin once scientists have prepared a sufficient quantity of cultivated cells.

Cells are the building blocks of meat and are carefully selected based on the desired end product, such as beef, poultry, pork and fish.

The process unfolds in several key steps:

- Preparation of bio-ink: The cultivated cells mix with bio-ink, a substance designed for 3D printing that supports cell life and growth. The bioink typically contains a mixture of nutrients and sometimes biodegradable materials that help to support structure.

- 3D printing: The bioink then goes into a 3D printer with programming to shape the food based on digital designs. The printer precisely deposits layers of bio-ink, following the design to mimic the texture and structure of traditional meat.

- Maturation: After printing, the product undergoes a phase where it’s kept in a controlled environment to allow the cells to fuse and form tissues. During this phase, the printed structure fully develops into a denser, thicker shape, resembling real meat.

After the meat has matured, it may undergo further processing, such as seasoning, marinating or combining other ingredients to enhance flavor and appeal. Once it’s ready, it can then be cooked and consumed like traditional meat.

What Are the Benefits of 3D Printed Meats?

Printing meat with the touch of a button has the potential to benefit the food industry in various ways.

Customization

One of the most exciting advantages of 3D-printed foods is their high customizability. Producers can adjust fat content, texture, flavor and nutritional profile. This allows the meat to cater to specific dietary needs and taste preferences. Plus, it could lead to healthier meat options with added vitamins and reduced cholesterol.

Scalability

Although still in its development stages, 3D-printed meat has the potential to be scaled up to meet the demands of a growing global population. As the technology matures and becomes more cost-effective, it could greatly reduce the pressure on traditional meat supply chains and offer a sustainable alternative where companies produce it closer to consumers.

Animal Welfare

The most ethically compelling aspect of 3D-printed meat is that it offers a slaughter-free alternative to meat production. By using animal cells without harm, it presents a future where meat consumption mitigates the killing of animals.

Eco-Friendliness

3D-printed meat has a significantly lower environmental footprint than livestock farming. It requires less land, water and energy, and produces fewer greenhouse gas emissions. This makes it a promising solution for reducing the environmental impact of people’s diets.

Quicker Production

The timeline from cell to steak is much shorter for 3D-printed meat than for raising animals. This efficiency means that companies can produce it quicker and respond more rapidly to market demand changes.

Is 3D Printed Meat a Healthier Alternative?

3D-printed food presents several health benefits by allowing nutritional customization, making it a healthier alternative to traditional beef. It enables producers to enhance the nutritional profile with beneficial components like omega-3 fatty acids while reducing harmful saturated fats.

This process greatly lowers the risk of contamination with antibiotics, hormones and pathogens common in meat production, thus offering a safer consumption option. Moreover, the lab-grown nature of this meat means it can be engineered to be free from common allergens, providing an option for those with food sensitivities.

The controlled production environment ensures consistent quality and safety, providing a healthier diet choice than red meat that can cause several health risks, including:

- Diabetes

- Heart disease

- Cancer

- Premature death

What Impact Could 3D Printed Meat Have in the Future?

3D printing technology in meat production brings transformation to the industry. By moving away from livestock farming to lab-grown meat production, this could reduce the need for resources and the amount of waste that restaurants and retailers produce.

3D meats also reduce carbon footprint because they can be produced closer to urban centers, thus minimizing transportation. As a sustainable and efficient protein source, these meats could address global food security challenges. It offers a way to meet the rising demand for protein as the global population grows. As such, it’s paving the way for a more sustainable and equitable future, helping develop a hunger-free world.

The Challenges of 3D Printed Meat

While 3D-printed meat holds promise for the food industry, it still faces some obstacles, such as the cost. Production remains high due to the technology itself and the growth mediums required.

While startups like Redefine Meat are focusing on making faux meat comparable to real ones — costing from $5 to $12 per pound — it will take time before production can meet global demand.

3D food printers range from $1,000 to $ 5000, but this excludes the industrial sizes needed to produce meat. Additionally, the estimate to make cultured meat at a lab is a $700 per kilogram expense, which most is spent to purchase the cell culture.

Another challenge is the production process. As you can imagine, cultivating meat requires explicit conditions and considerable resources. Therefore, meeting the needs at a large scale will be complex.

The Culinary Revolution of 3D Printed Meat

As the world ventures into the future of food, 3D-printed meat can be a solution to reduce environmental impact. It promises a world where dining meets ethical responsibility, and your plate holds the key to sustainability.

Taking on this innovation also opens the door to addressing some of the most pressing challenges of this time, including food security and global warming. Overall, 3D-printed meat from the lab to the table can be what’s needed to nourish the planet while preserving future generations.

Recent Stories

Follow Us On

Get the latest tech stories and news in seconds!

Sign up for our newsletter below to receive updates about technology trends