Automatons — better known by most as robots — have been a part of the collective human unconscious for a long time.

The ancient Hebrews and Greeks both made references to golems and mechanical assistants to aid humans in their pursuits. The word robot didn’t appear in literature until Karel Capek’s 1921 play “Rossum’s Universal Robots.” In 1926, the film “Metropolis” became the first moving picture to portray a human-looking robot on the silver screen.

Today, robots are a part of our daily lives. Even if we don’t cross paths, robots are now working in our warehouses and assembly plants, exploring distant planets, and helping us inspect our infrastructure sites and even build brand-new ones.

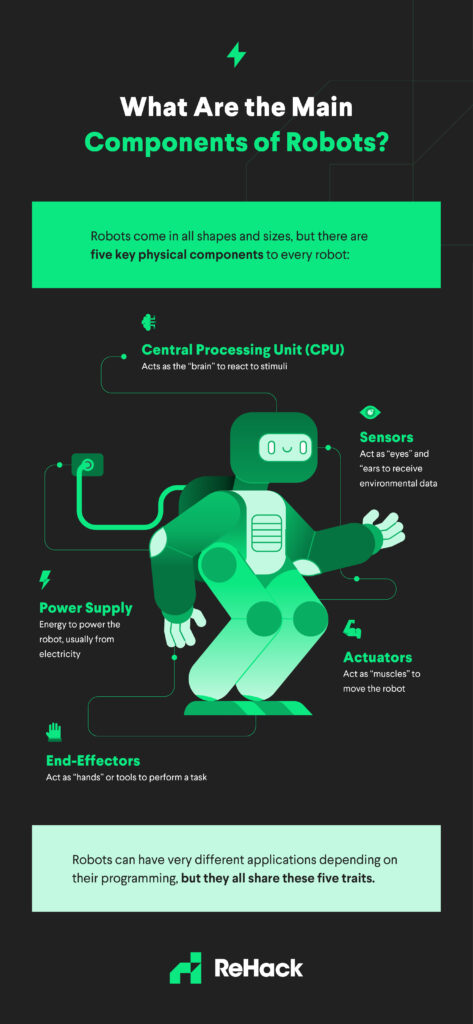

How do robots actually work, though? What are the key components to every robot, and how do they contribute to its overall functionality? Here are the five main components of robots:

1. Central Processing Unit

One of the main components of a robot is found in any computer-driven technology: the central processing unit (CPU). The CPU acts as the “brain” of the robot. In other words, a CPU is the robot component that provides feedback to outside stimuli.

All organisms function and survive by using feedback. It’s what causes us to whip our hands away after we’ve touched a hot stove. The CPU in a robot takes in environmental data using sensors and then calls on its programming to perform the appropriate action.

One of the earliest examples of using feedback to control a machine dates back to 1745 when Edmund Lee invented the automatic fantail. This device consisted of smaller vanes attached to the axle of a larger windmill that changed direction depending on the wind. This simple system may be a far cry from today’s CPUs, but the core idea, functioning according to outside feedback, remains the same.

In the anatomy of robots, CPUs function similarly to the human brain. Data comes in through sensors just as information comes to the neurons in your brain through your body’s senses, then the CPU interprets and acts accordingly.

2. Sensors

That takes us to the next key component of every robot: sensors. Sensors are the powerhouse of a robot’s feedback mechanism. They act as eyes and ears to help it take in information about its surroundings. Robots typically incorporate a wide range of sensor types to help them perform their work. These include:

- Light sensors

- Sound sensors

- Temperature sensors

- Contact sensors

- Proximity sensors

- Distance sensors

- Pressure sensors

- Positioning sensors

Contact and proximity sensors help robots navigate more confidently and safely, especially when deployed alongside human workers. Pressure sensors may control the grip strength of a powered robotic arm so it doesn’t crush the merchandise it’s processing.

Positioning sensors include GPS, digital magnetic compasses and other tools to approximate the location of a robot, either indoors or outdoors. Some robots also navigate their surroundings through vision sensors, which function like eyes. Cameras feed in visual information, and then an artificial intelligence (AI) process called machine vision analyzes the video footage to recognize objects, guiding the robot.

A newer but increasingly popular kind of robotic sensor is proprioceptive sensors. These components monitor a robot’s internal factors like heat, electric current and battery life. Since robots are often expensive, companies must stay on top of their maintenance, and this information helps them do that.

3. Actuators

If sensors are the eyes and ears of the robot, its actuators function like muscles. Actuators are small motors attached directly to the structure of the machine that facilitate movement. Some of the most common types include:

- Hydraulic: Uses oil to facilitate movement

- Pneumatic: Uses air to facilitate movement

- Electric: Uses electric current and magnets to facilitate movement

Hydraulic actuators typically appear in heavy machinery, including mining and construction equipment, since they produce a lot of force and are relatively easy to maintain. Pneumatic actuators have many of the same benefits and are often less expensive, but they’re sensitive to vibrations. They’re a popular choice for manufacturing and other stable, indoor settings.

Electric actuators are by far the most common type today. They provide more control, have fewer environmental hazards, make little to no noise and are easy to program.

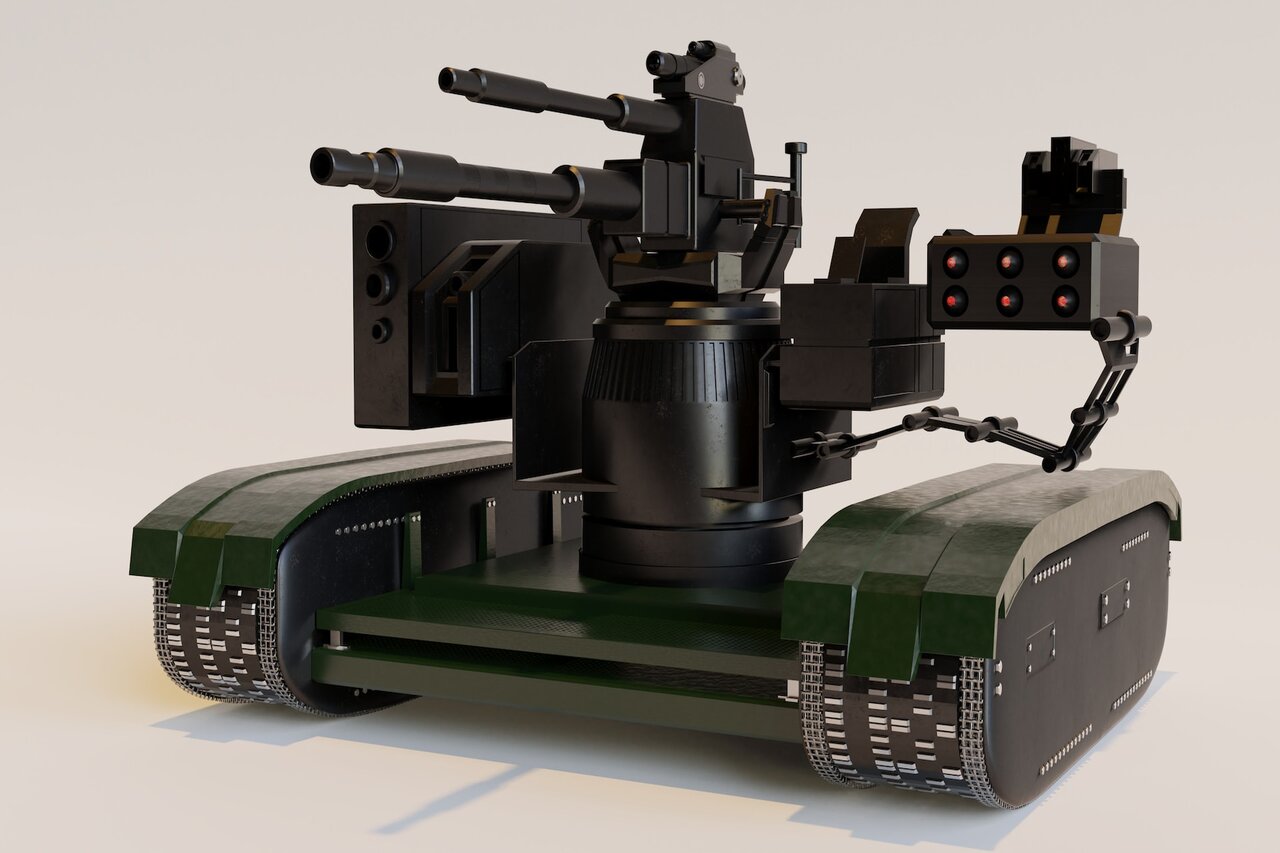

Some of the simplest robots consist of little more than an arm, an actuator and a tool for performing work. More complex robots may use actuators to kick treads, wheels or even legs into motion.

Step motors may be used when robots are deployed to complete delicate tasks that require finesses and accuracy. These are distinct motor designs that provide movement in specific intervals in a highly repeatable fashion.

The ability to realize consistently high-quality results through robots and step motors is one of the reasons why robotic assembly took off in such a huge way in the 1960s and never slowed down.

4. End-Effectors

Another quality that most robots have in common is end-effectors. The terms “effector” and “end-effector” are sometimes used interchangeably. Both terms refer to the tools aboard the robot — the parts that perform the actual work and interact with the environment or a workpiece. Here are a few examples:

- Factory robots may feature end-effectors such as welding torches, screwdrivers, rivet guns and paint sprayers.

- Mobile robots usually have manipulators and grippers for lifting objects or disposing of dangerous ordinance.

- Robots like those dispatched to other planets may carry shovels, drills, hammers, cameras, lights and other analytical implements.

From simple to complex, effectors allow robots to carry out their specific tasks with precision. For example, some of the latest robotic technology uses tiny scalpels, hands and cameras to perform surgery. These precise tools combined with robots’ stability and range of motion make surgery safer and less invasive. Some robots can perform operations with just a 25 mm incision, which would be far too small for a human to operate in.

5. Power Supply

Just like human beings consume food when they need energy, robots need energy to function as well. Almost all robots receive their power from electricity.

Power supplies can still take many different forms, however. Stationary robots, like those in factories, receive direct power just like any other appliance. Mobile robots typically sport high-capacity batteries, while robotic probes and satellites are generally equipped with solar panels for harvesting energy from the sun.

As energy conservation has become a more pressing issue, many robots today include power-saving features. Some automatically switch to a low-power mode according to their usage, others use unique designs to minimize mechanical motion and still more use green energy sources. As this trend continues, additional novel ways to reduce robots’ power consumption will emerge.

6. A Program

A robot’s programming isn’t a physical component, but it’s still an essential part of the whole. Each of the basic components of robots we’ve looked at takes in stimuli or provides a form of feedback. The program within a robot provides the logic that drives these behaviors.

You may be familiar with automation recipes, including “If This Then That” functionality. It’s a concept anyone can explore with their smartphones and smart homes. Robots, likewise, contain “logic trees” that gather and analyze task and environmental data, and then choose an appropriate response based on that stimulus.

For example, if a robot approaches a steep drop-off, it will back away automatically. A robotic probe exploring another world may activate a different tool depending on what its cameras and sensors detect around it.

Other robotic programming examples are more advanced. The latest automated technology uses machine learning, which mimics how humans learn. These robots continually take note of different situations and outcomes they encounter and learn from them. The longer they operate, the more they understand, becoming increasingly accurate and helpful.

Self-driving cars are an example of robotic systems that use machine learning. As companies test these vehicles on the road, they encounter more obstacles under more conditions, learning to identify them better. Without machine learning, these cars may not recognize every object they come across, which could be dangerous.

Human decision-making happens quickly enough that we’re usually not aware of doing so in the moment. The same general concept applies to getting robots to perform specific tasks in uncertain circumstances without much or any human interaction.

Robots and Progress Intertwined

Robots have long been a bellwether for the march of technological progress. Early attempts at these machines look halting and clumsy now when you consider the agility of something like Boston Dynamics’ robotic dog, “Spot.” Far from a toy, this $74,500 robot is capable of “almost limitless” applications, according to Boston Dynamics spokespeople, ranging from pulling heavy loads to conducting automated surveillance of private property.

The march continues. Over the coming years, we’ll soon see robots taking on an even wider variety of forms and carrying out many more tasks than they do today. From performing jobs for small businesses to building and maintaining some of the most impressive structures in the world, if there’s something to inspect, fabricate or carry, there’s probably a robot for that.

Want to dive deeper into robotics? Read What Are the Most Common Types of Robots?

Recent Stories

Follow Us On

Get the latest tech stories and news in seconds!

Sign up for our newsletter below to receive updates about technology trends